Product

SLUDGE CLEANER

SLUDGE CLEANER

This is an eco-friendly cleaner that uses compressed air to suction, filter, sterilize, and separate sludge, fine chips, floating substances, and more, and then drain them along with air.

Features

- No risk of explosion as it uses compressed air.

- Convenient and long-lasting to use.

- Enables separation of liquids and solids without machine downtime.

- Prevents cutting fluid decay through oxygen supply and sterilization treatment.

- Prevents occupational diseases through odor removal.

- Extends machine and tool lifespan through fine chip and sludge removal.

- Improving productivity and product precision.

- Enables removal of floating substances and residues.

- Reduces waste disposal and cutting fluid replacement costs.

- SD400 TC80A is capable of unmanned automatic operation.

Applications

- Suction, filtration, and injection of liquid and chip, sludge mixtures.

- Cleaning of water, cutting fluid, and oil tanks.

- Easy removal of sediment, floating substances, and remaining fluid.

-

SLUDGE

-

OIL CHIP MIXTURE

-

REMAINING FLUID

-

CUTTING FLUID

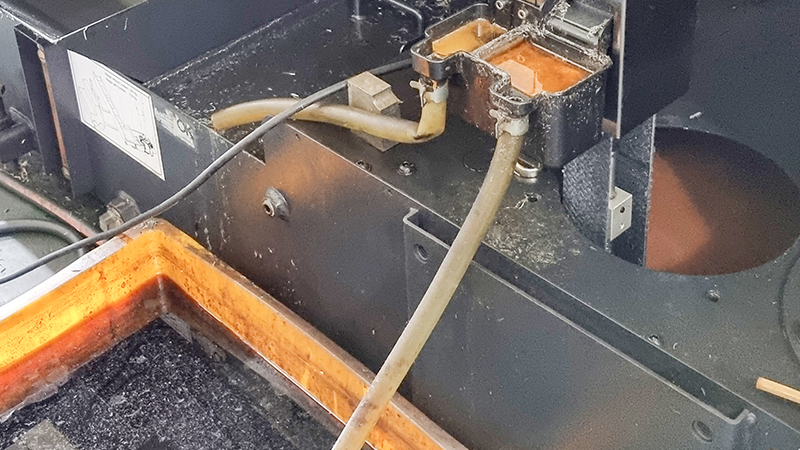

Cutting fluid and sludge suction

Cutting fluid and sludge suction Solid/liquid separation

Solid/liquid separation Discharge of filtered cutting fluid and oxygen supply

Discharge of filtered cutting fluid and oxygen supply Sterilization treatment of degraded cutting fluid Sterilization filter(optional)

Sterilization treatment of degraded cutting fluid Sterilization filter(optional) After separating collection tank, remove the sludge

After separating collection tank, remove the sludge

Specifications

| Model | Air Pressure | Vacuum | Air Consumption | Liquid Suction Capacity | Size | Weight | Capacity | Power | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| kgf/㎠ | psi | mmHg | mmAq | ℓ/min | SCFM | ℓ/min | (LxWxH) | kg | ℓ | ||

| SD400 TC80A |

4 | 57 | 240 | 3262 | 500 | 17.6 | 72 | 800x850x1050 | 53 | 80 | AC 220V60HZ |

| SD400 TC80M |

80 | 50 | - | ||||||||

| SD400 H35 |

800x320x320 | 5 | excluding drum |

||||||||

ㆍSpecifications, dimensions, etc. listed may be subject to change without prior notice for product improvement.